Harnessing endolysins to create the next generation of antibiotic-free solutions

Axitan is the leading biotech company focused on developing novel endolysin-based products to target and neutralize pathogenic bacteria impacting animal protein production & food safety

Who we are

To facilitate the safe reduction and removal of antibiotics through endolysin-based solutions

Our purpose

Why our technology matters

Antimicrobial resistance (“AMR”) is one of the major global health threats facing society. The overuse of antibiotics is recognized as the primary cause.

The median resistance of the common foodborne pathogens is now approaching 50%.

The animal protein industry accounts for around 66% of antibiotic consumption annually. Antibiotic consumption is forecast to increase 11.5% by 2030 in the sector (NIH).

Axitan’s technology provides a new mechanism for targeting & killing bacteria without causing resistance.

The cost of AMR

Human life

1.27m deaths pa today

10m by 2050 (O’Neill/UN)

Economic

$3.4tn per year by 2050 (WHO)

Food-borne illness

600m cases of food-borne illness, 420,000 deaths pa (WHO)

$110B in global impact made harder to address due to AMR

Endolysins

Fast effective, no antimicrobial resistance

How we use endolysins

Axitan has pioneered the discovery, development, production and formulation of unique endolysins to target and kill pathogenic bacteria.

What they are

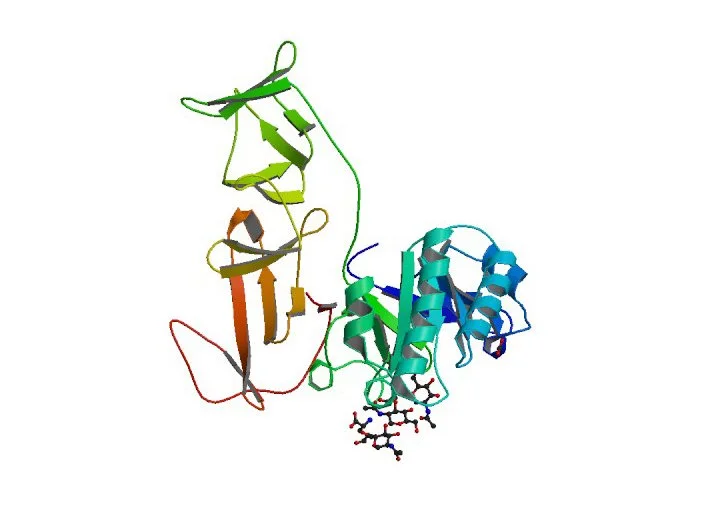

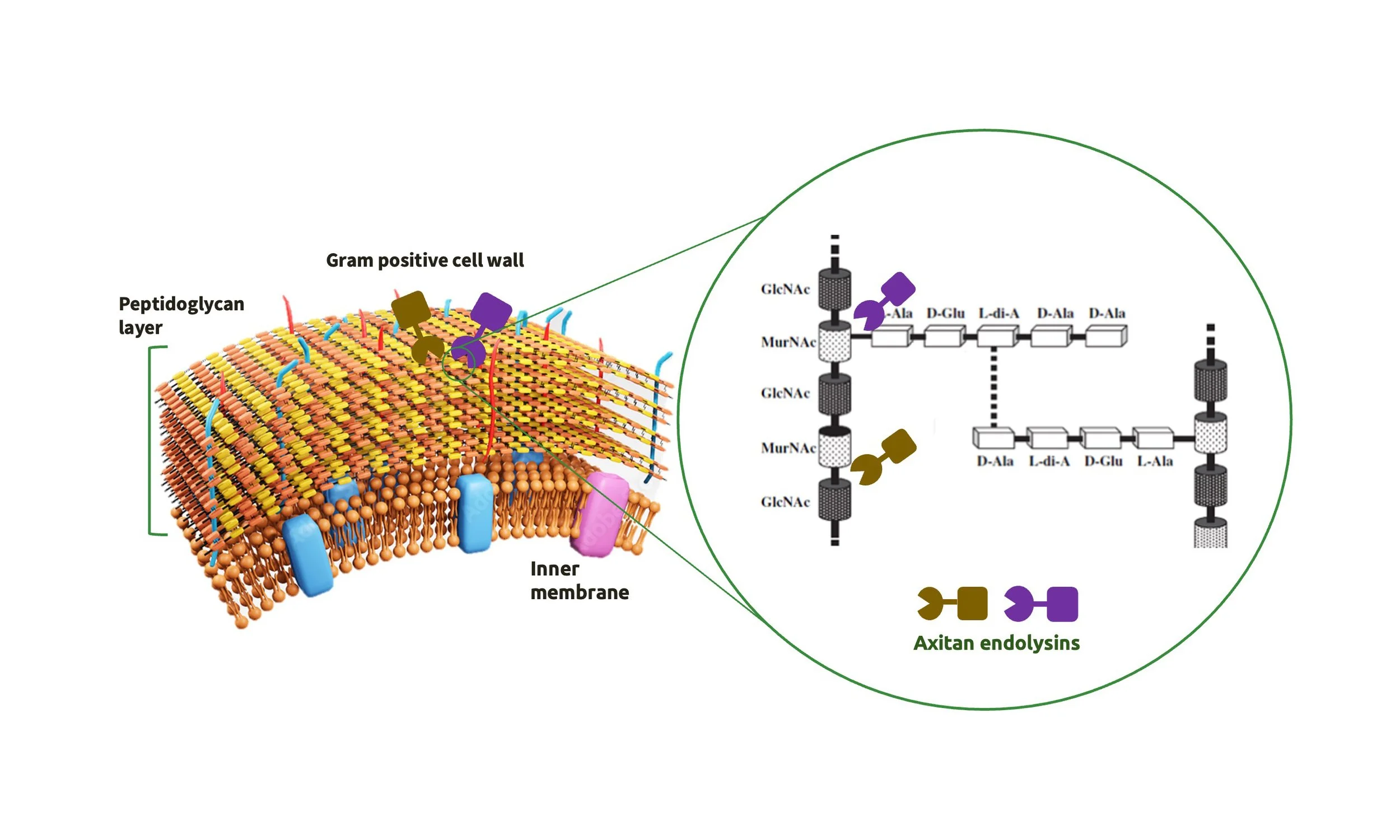

Endolysins are single function enzymes originally used by viruses to cut through cell-walls of infected cells so that a virus’s progeny can be released.

How they work

Endolysins comprise two domains

A targeted binding domain

Our endolysins only bind to the cell-wall of their intended target

A cutting domain

Whose sole function is to cut through the peptidoglycan layer (“cell-wall”) causing the cell to lyse (“burst and die”)

Why endolysins: an alternative to antibiotics

Have direct mode of action – ie. only cut the cell-wall of the targeted pathogen

Are not broad spectrum – only target their intended pathogen leaving good bacteria alone

Fully withstand commercial production processes and different production models

Can be easily formulated with other beneficial components to improve productivity

Do not trigger antimicrobial resistance

Real world applications

The animal protein industry accounts for around 66% of the world’s annual antibiotic consumption.

Our commercial products address key productivity issues arising from the animal protein industry’s drive to reduce antibiotic usage.

FORC3®

Targets Clostridium perfringens, the causative agent of necrotic enteritis in poultry. Has been seen to significantly improve livability & productivity, including FCR and meat yield, across multiple production models.

NMAN®

Our high-performance nutrition and hydration gel. The foundation for a strong immune system in chicks and poults. Has been seen to consistently improve livability & uniformity.